Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Manufacturing In 200/300/400 Series Stainless Steel Since 2004. 【Online Catalogs】

Email: marketing@mellowsteel.com

Tel/Whatsapp: +86 13827707434

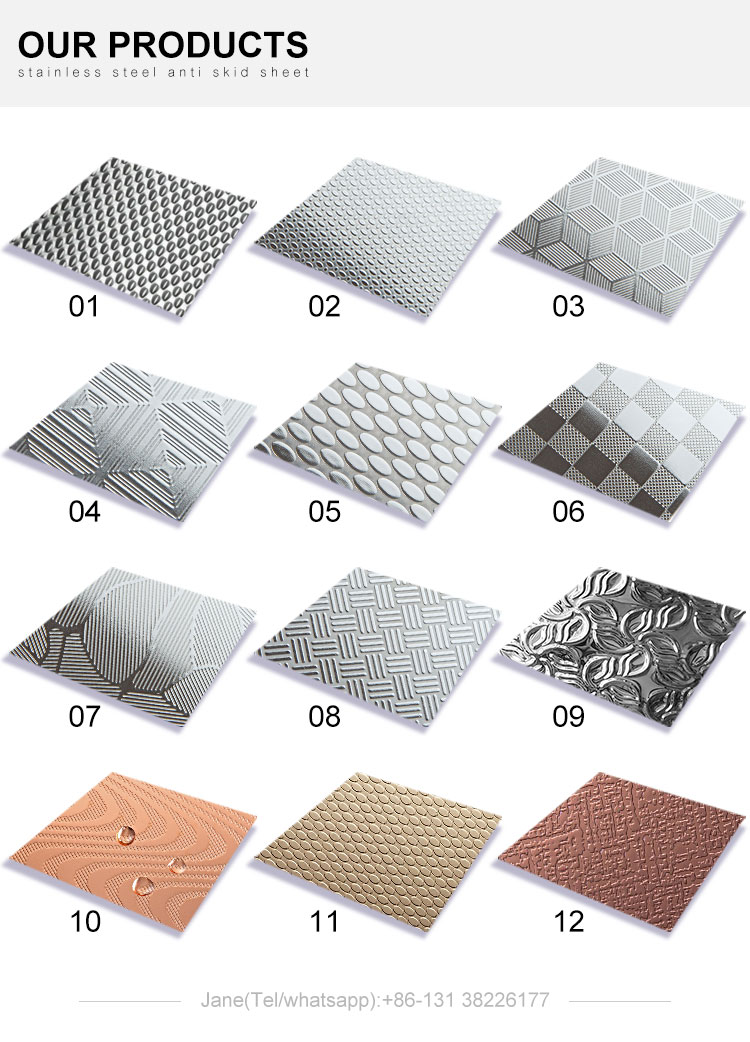

Product information

|

Brand |

|

|

Product |

304 embossed stainless steel |

|

Technique |

Hot Rolled / Cold Rolled |

|

Standard |

AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc |

|

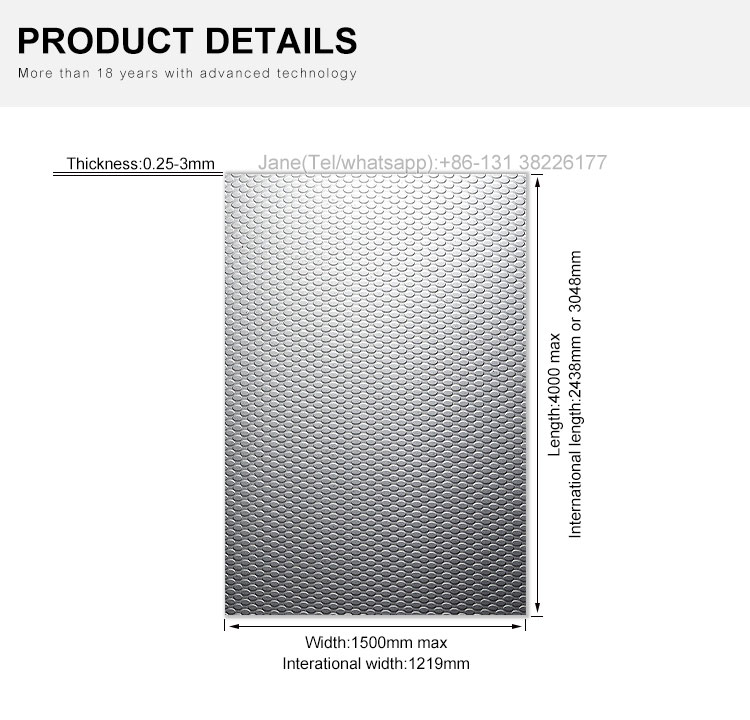

Width |

500mm/1000mm/1219mm/1250mm/1500mm/1800mm/2000mm/2200mm/2500mm/3000mm/3500mm, or as required |

|

Length |

500mm/1000mm/2000mm/2438mm/2500mm/3000mm/6000mm/8000mm—13000mm, or as required |

|

Thickness |

0.4/0.5/0.6/0.7/0.8/0.9/1.0/1.2/1.5/2.0/2.5/3.0/4.0/5.0/6.0/8.0/10.0/12.0/14.0/16.0—250mm, or as required |

|

Material |

201, 202 |

|

Color |

Standard RAL color: Red, Blue, White, Grey, Brick, etc. |

|

Stock Dimension |

Cold Rolled: 0.4-6.0mm*1000*2000mm/ 1220*2440mm/ 1250*2500mm/ 1500*3000mm, or as your request |

|

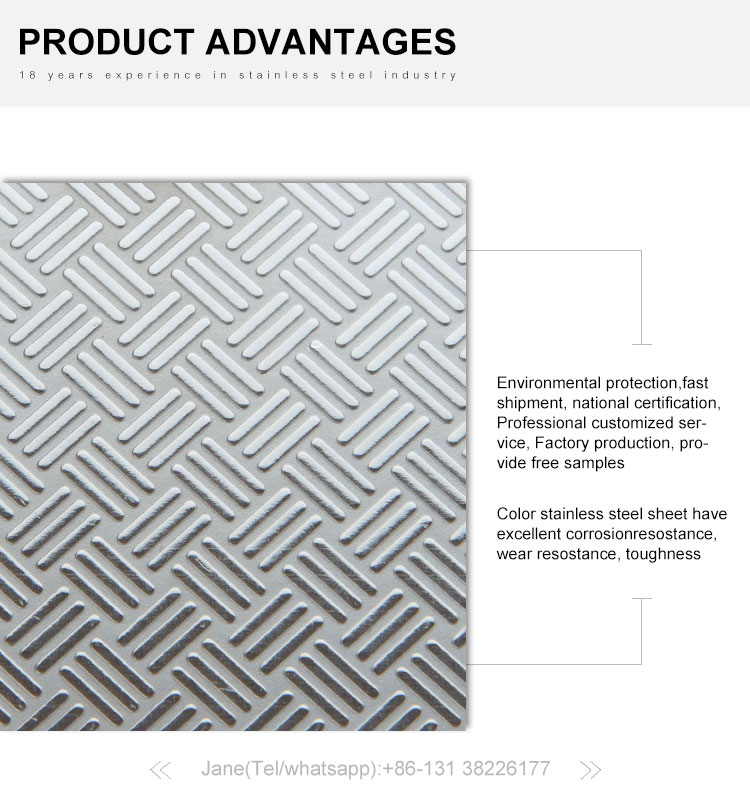

Service |

OEM, Customized processing service, Customized fabrication by drawings |

|

Processing Type |

Cutting, Bending, Stamping, Welding, CNC machining |

FAQS

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials. .

Q:What are the certifications for your products?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-45 days, and may be delayed if the demand isextremely large or special circumstances occur.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Q:How to pack the products?

A:The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It caneffectively protect products from corrosion during ocean transportation.

Copyright © 2004-2022 Foshan Mellow Stainless Steel Co., Ltd. | All Rights Reserved 粤ICP备19129739号 Sitemap Kinlife Group Kinlife Boat Kindlemetal Stainless Steel Kitchen